Cast and machined components

for your products

for your products

Foundry

Plant 1

- Materials: Ductile and Grey Iron.

- Total Melt Capacity: 11,500 tonnes per year.

- Total Raw Casting Capacity: 7,500 tonnes per year.

- Molding System: Phenolic Urethane No Bake-Cold Box

- Melting System: Medium Frequency Induction Furnaces

- Maximum Casting Size: 58” x 40” x 40” (1470 mm x 1000 mm x 1000

mm) - Minimum Raw Casting Weight per Mold: 55 kg (120 lbs) *Depends in

casting size and number of prints per mold (EAU). - Maximum Raw Casting Weight per Mold: 1100 kg (2,220 lbs)

- Minimum Casting Wall Thickness: .250” (6.35 mm) *Consult if lower.

- Geometrical Casting Tolerance Grade per ISO 8062-2007: CT 8-9 *Consult

if lower. - Full Finish, Shot Blast, and Primer capabilities

- Actual Productive Area: 4 Hectare (431,000 sq ft).

- Total Area for Future Expansion: 10 Hectare (1,080,000 sq ft).

- Full sand and metallurgical laboratory including Casting Simulation.

Capabilities

Plant 1

- Part unitary weight range 60 Lbs. to 1000 Lbs.

- Part envelop up to: 50″x40″ 20″/20″

Plant 2

- Part unitary weight range 100 Lbs. to 3300 Lbs.

Iron Grades

Gray Iron

- CL-25

- CL-30

- CL-35

- CL-40

Ductile Iron

- 65-45-12

- 60-40-18

- 80-55-06

- 100-70-06

Mold Making

2 fully automatics pep set system palmer molding lopps.

- Continuous Mixer: 750 pounds/Min.

- “C” Frame Rollover to handle 1/2 mold up to 53″x40″x20″.

- Up to 8 patterns (Cope & Drap) in the loop.

- Up to 30 molds per hour.

- Core setting and mold closing lines with powered mold handlers.

Core Making

CB 22 Redford Vertically parted Cold Box Core Blower Machine.

- 22″x27″x27″ Plates.

- Continuous Mixer: 150 Lbs/Min.

- 220 Lbs. Sand Hopper.

- Additives mixing capabilities.

- Blogger Cores produced in Molding Loop.

Core Room

- Laempe L 40-100

- Redford Craford CB-22

- Palmer M-200 Continuous Mixer

- Core Assembly and Wash Line

Melting

4 Pillar 750 Kw Power Track with 4 1MT furnaces.

Cleaning

- Cutting, deburring grinding and cleaning equipment.

- 70″x70″x80″ Pangbom Rotoblast machine with dust collector.

- Goff 36″ Rotating plate shotblast machine with dust collector.

- Empire 28″ Rotating plate shotblast machine (Interior) with dust collector.

Sand Reclamation System

Fully automatic mechanical and thermal reclamation system

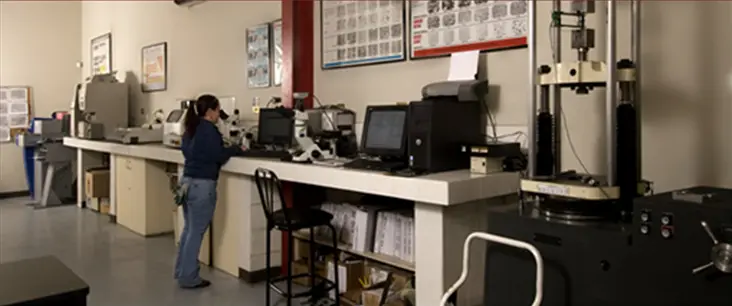

Laboratory Equipment

Melt Lab

- Leco Model C200 4012.

- Spectro Maxx 121019/06.

- Spectro ARL 3460.

- Metalographic microscope Olympus.

- Stereo-Optic microscope (Computer Image Analizer).

- Samples test cutting, grinding, polishing and cleaning equipment.

Sand Lab

- W.S. Tyler Sand Test Sieve (Ro-Tap).

- Electronic laboratory scale .01 gram resolution.

- Thermolyne 1500 Furnace (LOI Test).

- Drying Chamber Oven series 9000.

- PH and Moisture Analyzer equipment.

- Dietert 405-0071 Universal Machine for Sand (with all accesories).

- Manual mold sand hardness tester.

- Manual mold sand tester.

Physical Test

- Newage 362 Bench Brinell Hardness Tester.

- Newage VX66 Portable Brinell Hardness Tester.

- Newage 792 Highlight Brinell Scope Microscope.

Mechanicals Test

- Tinius Olsen 98565 Universal Machine.

- Computer System for Graphics.

- Epsilon E84124 Extensometer.

Plant 2

Overview

- Materials: Ductile and Grey Iron.

- Total Melt Capacity: 14,400 tonnes per year

- Total Raw Casting Capacity: 10,000 tonnes per year

- Molding System: Phenolic Urethane No Bake-Cold Box

- Melting System: Medium Frequency Induction Furnaces

- Maximum Casting Size: 62” x 57” x 44” (1560 mm x 1450 mm x 1120 mm)

- Minimum Raw Casting Weight per Mold: 200 kg (440 lbs) *Depends in casting size and number of

prints per mold (EAU). - Maximum Raw Casting Weight per Mold: 1500 kg (3,300 lbs)

- Minimum Casting Wall Thickness: .250” (6.35 mm) *Consult if lower.

- Geometrical Casting Tolerance Grade per ISO 8062-2007: CT 8-9 *Consult if lower.

- Full Finish, Shot Blast, and Primer Capabilities

- Stress Relief Heat Treatment outsource in House in 2022.

- Actual Productive Area: 4 Hectare (431,000 sq ft).

- Total Area for Future Expansion: 10 Hectare (1,080,000 sq ft).

- Full sand and metallurgical laboratory including Casting Simulation.

Molding

- Omega Foundry Machinery & Tinker Omega Sinto.

- Capability: 14 molds per hour.

- Full Automatic Molding Carrousel Loop with IOT Technologies such as:

1. Flow Master – Coriolis Meter for automatic calibration and monitor of resin delivery.

2. Catalyst Temperature Bias – Mold Strip time consistent as automatic compensation of catalyst

percent to keep the cycle time consistent.

3. Smart Gate for automatic sand flow control and sand blending (thermal -mechanical

reclaimed and new sand)

4. Sand Heater-Cooler Classifier above mixer with automatic sand temperature control in a

range of +/- 5° C and Magnehelic gauge for fines control.

5. RFID Pattern Recognition: Automatic control of Sand, Binder, and Compaction per Pattern.

6. Auto Teach.

7. Alarm Diagnostics.

8. Remote PC access

9. Integrated Cycle time control with Barrel Type Rollover for pattern strip, In-Line Tilt Flow

Coater for mold wash application, Flame Off Station for emissions control, automatic band

roller conveyors for mold transport, coring and mold assembly.

All of the equipment is integrated with NextGen 2 & 3 systems for a complete automatic

process, productivity, and materials control.

Melting

- Inductotherm Corp. – AMV – Meltlab – Acertac

- Two 2.2 tonnes Medium Frequency (500 Hz) Duraline Furnaces.

- Capacity: 14,400 tonnes per annum.

- Fully integrated with IOT connectivity for Melt Control, Data Mining, Alarm

and Diagnostics Logging with Melt-Manager® Plus® Control Systems. - Remote IOT Chemistry Control, Charge Materials Purchase and Stock

Management and Optimization with the integration of AMV´s ALEA

Optimization Software, Thermo Scientific ARL – SpectroMax Spectrometers,

Various Weight Systems, and Synchro MRP (Materials Resource Planner). - Environmental conscious Hybrid Adiabatic-Dry Cooling Tower

- Each furnace with Modular Fume Extraction and Furnace Lids for air quality

and energy savings. - Thermal Analysis Quality Control.

- Energy Efficient Geared Extended Spout Teapot Pouring Ladle for consistent pouring and casting quality.

Cooling

- Tinker Omega Sinto.

- Semi-Automatic Pouring and Cooling lines to provide production flexibility and mold cooling time control.

- This benefits in better dimensional control and lower thermal stressed castings in a consistent manner.

Reclamation

- Omega Foundry Machinery & Tinker Omega.}

- Automatic Mechanical Reclamation: Shakeout Grid – Attrition Mill – Magnetic Separator – Cooler

Classifier – Pneumatic Transportation – Storage Silos. *Dust control system and Bag Houses. - Automatic Thermal Reclamation: Fluidized Gas Combustion bed – Cooler Classifier – Pneumatic

Transportation – Storage Silos. *Dust control system and Bag Houses.

Finishing and Coating

Pangborn Hanger Shot Blast Machine

Primer Boot

Future Expansion

Future Stress Relief Heat Treatment